E1 vs. ENF Grade Boards: The Ultimate Guide to Eco-Friendly Standards in Hotel Furniture

Discover STARJOY’s guide on E1 vs. ENF grade boards, highlighting eco-friendly standards for custom hotel furniture factory solutions. Learn how to choose sustainable materials that ensure safety, durability, and environmental responsibility for High Quality hotel furniture production.

- 1. Introduction: Why Formaldehyde Standards Matter in Hospitality

- 2. Understanding the Technical Differences: E1 vs. E0 vs. ENF

- 3. Application Strategies: Choosing the Right Grade for Each Hotel Area

- 4. The ROI of Sustainability: Faster Project Turnover

- 5. How Starjoy Global Ensures Material Excellence

- Conclusion: Making the Smart Choice for Your Project

- FAQ

1. Introduction: Why Formaldehyde Standards Matter in Hospitality

The Invisible Threat

Formaldehyde is one of the most common—and most overlooked—sources of indoor air pollution in furniture and interior fit-outs. Released slowly from composite wood boards and adhesives, excessive formaldehyde emissions can negatively affect indoor air quality, causing respiratory irritation and long-term health concerns.

Rising Guest Expectations

Today’s travelers are far more health-conscious. The concept of the “green hotel” has evolved from a marketing differentiator into a baseline expectation. As a professional custom hotel furniture factory, we have observed that guests now directly associate air quality and odor-free rooms with overall brand luxury.

The Evolution of Standards

While E1 grade boards were once the industry norm, global hotel brands are now moving toward E0 and ENF grades. This shift reflects a broader commitment to environmental accountability and guest well-being.

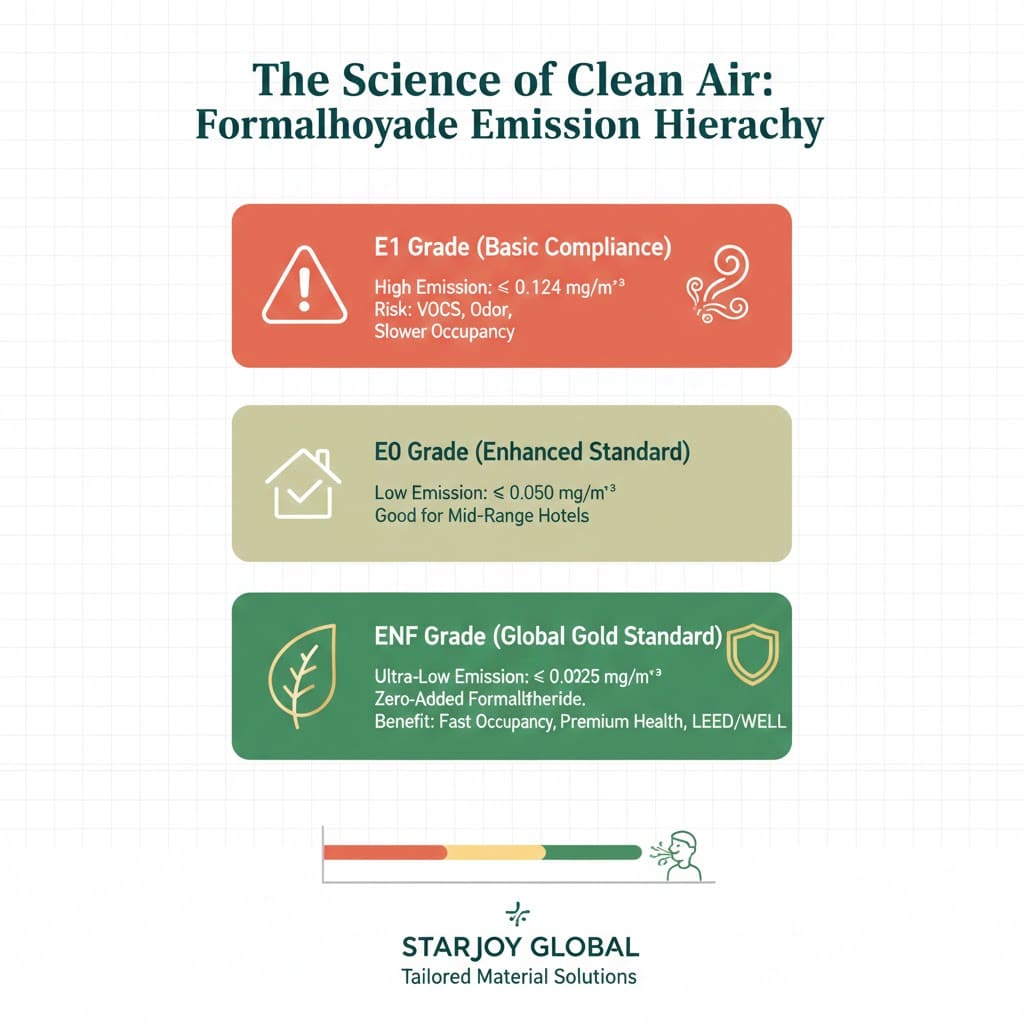

2. Understanding the Technical Differences: E1 vs. E0 vs. ENF

The key difference between board grades lies in their allowable formaldehyde emission limits.

| Board Grade | Emission Limit | Industry Positioning | Global Equivalents |

| E1 Grade | ≤ 0.124 mg/m³ | Mandatory baseline standard | Compliance level |

| E0 Grade | ≤ 0.050 mg/m³ | High-standard benchmark | CARB Phase 2 (USA) |

| ENF Grade | ≤ 0.025 mg/m³ | Ultra-low "Zero-Added" level | F★★★★ (Japan) |

The “Zero-Addition” Concept

ENF-grade boards (No-Formaldehyde Added) utilize MDI-based resins instead of traditional urea-formaldehyde glues. As a leading custom hotel furniture factory, Starjoy Global prioritizes these materials to push emissions to the lowest practical limit, ensuring your furniture is safe from day one.

3. Application Strategies: Choosing the Right Grade for Each Hotel Area

Guest Rooms: The Primary Focus

Guest rooms are enclosed spaces where occupants spend 8–12 hours a day. For these areas, furniture should use at least E0 grade, with ENF strongly recommended for 5-star and international-brand projects.

Public Areas: Lobbies & Corridors

Lobbies and corridors benefit from high air-circulation volumes. In these zones, E1 grade boards may offer a strategic balance between compliance and cost-efficiency, provided the manufacturer maintains strict batch testing.

4. The ROI of Sustainability: Faster Project Turnover

The "Opening Day" Financial Advantage

For hotel owners, the real value of high-grade materials is speed.

-

Traditional E1 Furniture: May require 15–30 days of high-intensity ventilation before a room is guest-ready.

-

Starjoy ENF Solutions: Rooms furnished by our custom hotel furniture factory using ENF-grade boards can often be occupied within 3–5 days of installation.

By reducing post-installation downtime, you can save weeks of lost revenue and accelerate your project’s ROI.

5. How Starjoy Global Ensures Material Excellence

As a top-tier custom hotel furniture factory with over 56,000㎡ of production space, Starjoy Global maintains total control over the supply chain:

-

Verified Global Sourcing: We partner with industry leaders like Wanhua and Kronospan to ensure consistent access to certified ENF materials.

-

Internal Inspection Protocols: Every batch of raw material undergoes formaldehyde testing to ensure strict alignment with your project specifications.

-

Global Compatibility: Our materials are fully compatible with international certifications, including LEED, WELL, and local fire-safety regulations.

Conclusion: Making the Smart Choice for Your Project

E1 grade meets the baseline, but ENF represents the future of hospitality. A balanced, zone-based material strategy—guided by an experienced custom hotel furniture factory—delivers both cost efficiency and long-term brand protection.

[CTA] Confused about material standards?

Contact Starjoy Global today for a free material consultation and a customized quotation tailored to your hotel project’s specific needs.

FAQ

Q: Is ENF grade 100% formaldehyde-free?

A: Natural wood contains trace amounts of formaldehyde. The ENF grade represents the lowest level achievable by eliminating added formaldehyde during the manufacturing process.

Q: Can I combine different grades in one project to control costs?

A: Yes. Many developers specify ENF for guest rooms to ensure guest safety and use E1 or E0 in large, well-ventilated public areas.

Q: Does the ENF grade affect the durability of the furniture?

A: No. Modern NAF (No-Added Formaldehyde) adhesive systems used in our custom hotel furniture factory maintain bonding strength and structural performance comparable to—or better than—traditional resins.

How to Make Your Desk Chair More Comfortable: 6 Expert Tips

Starjoy Hotel Furniture: Crafting Premium Hospitality Spaces with Custom Solutions

The Hidden Costs of Cheap Hotel Furniture: Why Low Initial Prices Can Ruin Your Hotel’s ROI

Why Global Hotels Prefer Working with Chinese Furniture Manufacturers (and How to Find the Best One)

Why Custom Luxury Hotel Lobby Furniture is Your Brand’s Most Important Investment

Why Choose STARJOY

Why choose STARJOY?

1) We have perfect hotel furniture project implementation capabilities: we have a professional in-depth design team, an efficient production team, and an experienced and friendly after-sale service team.

2) Our product quality is worthy of customer trust.

3) We have a flexible pricing system.

4) We have a strong willingness to cooperate.

About Cooperation Process

How to sign a cooperation agreement?

We will provide you with a draft cooperation agreement, which will be signed by both parties after confirmation to ensure the legality and standardization of the cooperation process.

What steps are involved in the cooperation process?

The cooperation process mainly includes demand communication, quotation, contract signing, in-depth design confirmation and material sample confirmation, production, quality inspection, logistics distribution, etc.

Products

What's the price of your model room?

Usually it is 2 times the price. Of course, if the negotiation is better, it can be more favorable. The price is negotiable.

About Products and Services

How do you ensure the quality of your products?

All products are produced in accordance with export quality standard and have passed quality, safety and environmental protection certification. We ensure that every product is strictly inspected to meet the safety and quality requirements of the international market.

Get in Touch

We strive to provide the most thoughtful service, excellent quality and value to every customer who customizes hotel furniture from STARJOY. If you have any questions about your order, please contact us.